No products

Prices are tax excluded

Smart wireless coating thickness meter

Transfer your coating thickness measurement data via Bluetooth to your tablet or smartphone - Precision coating thickness gauge with digital sensor - Smart app for statistical evaluation of data

Offline wet application system for tanks

Offline wet enamel application system for large storage tanks, water heaters & solar boilers. Repeatable processes optimized for every tank (family) thanks to industrial PLC which can store upto 30 individual programs.

Wall-mounted Manual Powder Enamel System

This Encore manual powder coating system is designed for rugged, everyday use, within an industrial enameling plant.

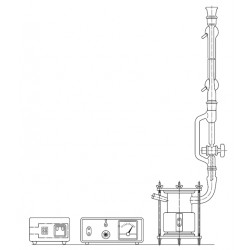

Test apparatus according to ISO 28706-2

This test equipment is used for the determination of the resistance of flat surfaces of vitreous and porcelain enamels to boiling acids, boiling neutral liquids and/or their vapours, according to ISO 28706-2.

Furnace tracker with thermal barrier

Furnace tracker for determining the temperature profile of porcelain/vitreous enameling furnaces.

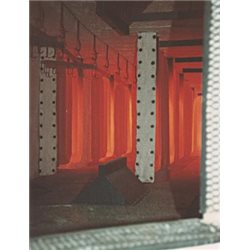

Gas fired continuous enameling furnace

Gas fired low thermal mass continuous enameling furnace with overhead conveyor - low specific energy consumption - excellent firing curve - available in many sizes & configurations

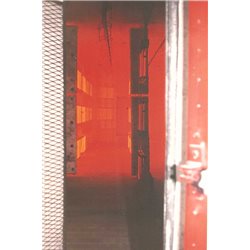

Electrical heated continuous enameling...

Electrical heated low thermal mass continuous enameling furnace with overhead conveyor - low specific energy consumption - excellent firing curve - available in many sizes & configurations

Stop & Go enameling furnaces

Compact enameling furnace with overhead conveyor for moderated volume of large products. - Small footprint - Energy efficient - Available in several sizes with gas or electrical heating

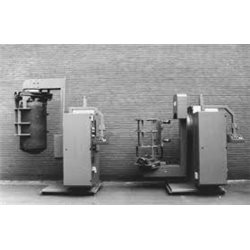

Pickling systems

Manual & automatic pickling systems for pretreatment at traditional enameling processes

Thermal imaging camera for smart phones

This compact lightweight thermal imaging camera plugs directly into your smartphone. - Great tool for troubleshooting industrial equipment - High resolution video's and photo's - Wide field of view

Online powder enamel system for water...

Engineered powder enamel application systems for internal coating of water heaters & solar boilers - Automatic loading & unloading - Recovery of overspayed enamel

Offline powder enamel system for water...

Engineered powder enamel application systems for internal coating of water heaters & solar boilers - Manual loading & unloading - Recovery of overspayed enamel

Double action diaphragm pump 1"

Heavy duty air operated double action diaphragm pump for wet enamels.

1 756,50 € 2 342,00 € -25%Online onlyIn StockStorage tank for wet enamel slip

Storage tank for wet enamel slip c/w electrical driven aggitator.

1 442,50 € 2 885,00 € -50%In StockNordson Encore inline powder pump

Nordson's Encore Inline Powder pump

172,20 € 287,00 € -40%Online onlyIn StockIon Collector kit for Nordson Encore PE guns

This user-adjustable ion collector may improve the smoothness and appearance of powder enamel coatings. Limited stock available.

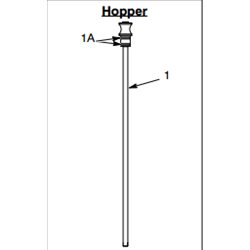

80,00 € 106,00 €Online onlyIn StockPowder pickup tube

Pickup tube for 80LB hopper with Encore pump mount

25,79 € 32,24 € -20%Online onlyIn StockRemaille, liquid cold enamel, in 20 ml...

Remaille is a liquid cold enamel which is commonly used for repairing enamelled surfaces and ceramics.Available in 21 different colors Fast worldwide delivery from our warehouse in the NetherlandsChoose your color by clicking on the thumbnail !

6,90 € 7,90 €Online onlyIn StockAntistatic powder hose 11 mm / 0.41 inch ID

TUBING,PWDR,ANTISTATIC 11MM (.43 IN) ID

6,51 € 8,14 € -20%Online onlyIn Stock

Remaille, liquid cold enamel, in 20 ml...

Remaille is a liquid cold enamel which is commonly used for repairing enamelled surfaces and ceramics.Available in 21 different colors Fast worldwide delivery from our warehouse in the NetherlandsChoose your color by clicking on the thumbnail !

6,90 € 7,90 €In StockRemaille, liquid cold enamel, in 250 ml tin

Remaille is a liquid cold enamel which is commonly used for repairing enamelled surfaces and ceramics.Available in 21 different colors Fast worldwide delivery from our warehouse in the NetherlandsChoose your color by clicking on the tumbnail !

31,90 €In StockRepair kit for enamel, ceramic & acryl

For the professional repair of minor damage and chipping in kitchen and bathroom.

27,90 €Out of stock

- No new products at this time.

RECENT POSTS

Fast worldwide delivery

We deliver worldwide and use for our transports only first class shipping companies.

Customer Service

You may reach us by phone on +31-(0)78-6169877 during working days between 08:00 and 18:00 CET. Alternatively you may send an e-mail to info@ditmer.nl

Payments

We accept payments via bank, major credit cards and PayPal.

About Us

Ditmer Trading & Consulting BV is a family owned & operated company, which is incorporated in november 2007 by Ronald Ditmer

We deliver worldwide machines, components, instruments & other supplies for the coating industry to authorities, companies & end-users.