No products

Prices are tax excluded

Catalog

Welcome to our webshop category dedicated to industrial enameling furnaces and their components.

Here, you will find a comprehensive range of state-of-the-art enameling furnaces for continuous & batch production and laboratory ovens that ensure precise temperature control and uniform heat distribution.

In addition to these furnaces, we off...

Welcome to our webshop category dedicated to industrial enameling furnaces and their components.

Here, you will find a comprehensive range of state-of-the-art enameling furnaces for continuous & batch production and laboratory ovens that ensure precise temperature control and uniform heat distribution.

In addition to these furnaces, we offer a variety of components that are crucial for the enameling process.

From heating elements and temperature sensors to conveyor systems and firing tools.

Last but not least, we offer various process control equipment for your furnace.

Enamel firing There are 44 products.

Subcategories

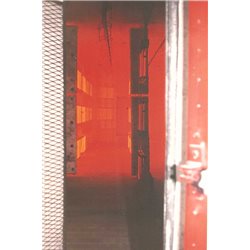

Continuous furnaces

Gas fired & electrical heated continuous furnaces for industrial enameling.

Batch furnaces

Batch furnaces for industrial enameling. Typically used for small volumes of large products

Laboratory furnaces

Laboratory furnaces from 36 upto 200 liter chamber volume

Burning tools

Firing tools for industrial enameling furnaces. Standard & customer specific solutions manufactured in various type of heat resisting alloy.

Furnace testing

Common equipment & instruments for testing/inspecting enameling furnaces

Gas fired continuous enameling furnace

Gas fired low thermal mass continuous enameling furnace with overhead conveyor - low specific energy consumption - excellent firing curve - available in many sizes & configurations

Electrical heated continuous enameling...

Electrical heated low thermal mass continuous enameling furnace with overhead conveyor - low specific energy consumption - excellent firing curve - available in many sizes & configurations

Stop & Go enameling furnaces

Compact enameling furnace with overhead conveyor for moderated volume of large products. - Small footprint - Energy efficient - Available in several sizes with gas or electrical heating

Electrical heated box furnace with...

Heavy duty electrical heated box furnace with extractable bottom - 1 m3 content - Kanthal-type heating elements - Firing cycle controlled by programmable micro-processor - Temperature uniformity +/- 3 degrees

Electrical heated box furnace

Heavy duty electrical heated box furnace with fixed bottom - 1 m3 content - Kanthal-type heating elements - Firing cycle controlled by programmable micro-processor - Temperature uniformity +/- 3 degrees

Laboratory furnace

Electrical heated general purpose chamber furnace for rapid offline testing of enamels

Gradient furnace

Classic gradient furnace for evaluation of enamel properties at various firing temperatures.

Furnace tracker with thermal barrier

Furnace tracker for determining the temperature profile of porcelain/vitreous enameling furnaces.