No products

Prices are tax excluded

Traditional vitreous enamel preparation

Traditionally wet enamel slip is prepared in-house by weighting, mixing & milling the necessary raw materials.

Upon completion of the milling process, the enamel slip is stored overnight to mature.

Below some images of equipment typically used for traditional wet enamel slip preparation.

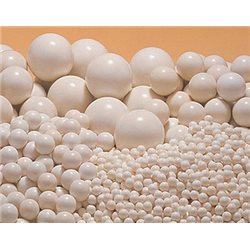

Heavy duty ball mill for preparing enamel and/or ceramic slurry prior to application.300 litres content High quality Alubit lining Heavy duty air operated double action diaphragm pump for wet enamels. For accurately measuring the amount of water used at enamel milling and/or mixing operations. Flexible but ridgid hose for pumping wet enamel slip. Alumina grinding balls in various diameters - fast & efficient enamel preparation - suitable for heavy duty operation Magnetic separator for removing iron particles from enamel slip. Mobile discharge unit for transport of enamel slip For sieving wet enamel slip after milling, mixing and/or recycling. Available in several size. 300 liter ball mill

Double action diaphragm pump 1"

GPI water meter type 01N12LM

Wet enamel transport hose

Grinding balls

Magnetic separator

Discharge unit

Vibrating screen sieve