No products

Prices are tax excluded

Catalog

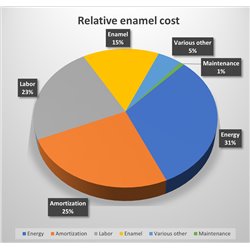

This product category includes various engineered & standard machines, test equipment & instruments and other supplies for industrial porcelain/vitreous enameling processes.

Vitreous Enameling There are 222 products.

Subcategories

Pretreatment

Various machines & related test equipment for metal pretreatment process prior to enamel application.

Enamel preparation

Various equipment for preparation & storage of wet enamel

Enamel application

Various industrial application equipment for wet enamel & powder enamel. See subcategories below for more info/products.

Enamel firing

Welcome to our webshop category dedicated to industrial enameling furnaces and their components.

Here, you will find a comprehensive range of state-of-the-art enameling furnaces for continuous & batch production and laboratory ovens that ensure precise temperature control and uniform heat distribution.

In addition to these furnaces, we offer a variety of components that are crucial for the enameling process.

From heating elements and temperature sensors to conveyor systems and firing tools.

Last but not least, we offer various process control equipment for your furnace.

Testing

Various testing & inspection equipment typically used for process and/or quality control of porcelain (vitreous) enameled coatings.

Spare parts

Services

Various professional services related to the vitreous enameling industry

Literature

Various manuals, standards & other background information about porcelain (vitreous) enameling

Enamel repair

Various materials for reparing defective enamel coatings

Software

Standard wheel blasting machines

Wheel blasting machine with Y track monorail for a non-continuous cleaning of different types of work pieces.

Electrical heated box furnace

Heavy duty electrical heated box furnace with fixed bottom - 1 m3 content - Kanthal-type heating elements - Firing cycle controlled by programmable micro-processor - Temperature uniformity +/- 3 degrees

Electrical heated box furnace with...

Heavy duty electrical heated box furnace with extractable bottom - 1 m3 content - Kanthal-type heating elements - Firing cycle controlled by programmable micro-processor - Temperature uniformity +/- 3 degrees

Automatic powder enamel spray gun

SPRAY GUN,AUTO,BAR MT,ENCORE PE

Classical "Banana" Gauge

Magnetic non-destructive coating thickness gauge for all non-magnetic coatings on steel and electro nickel on steel. No power supply No calibration Fully automatic

Feasibility studies

Feasibility studies for green field enameling projects, based on more then 40 years experience within the vitreous enameling industry.

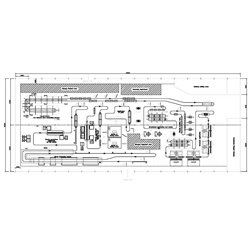

Designing factory lay-outs for enameling...

Designing enameling plant layouts, based on more then 40 years experience with capital goods within the vitreous enameling industry.

Factory audits & inspections

Professional consultancy services & hands-on project management support, based on more then 30 years experience within the vitreous enameling industry.