No products

Prices are tax excluded

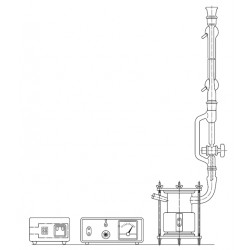

Portable porosity tester / spark tester acc. to DIN 55 670

New product

Portable spark tester for porosity measurements according to DIN 55 670.

Available with various probes and electrodes to test insulating coatings on metals.

More info

Corrosion protecting properties of coatings depend on the constituent parts of the material and

on how well the coating provides complete coverage of the surface.

If the coating is not spread adequately a burst air bubble in the coating film can lead to

a so-called pore through which corrosive influences can reach the surface to be protected.

Modern pore test instruments make use of the conducting properties of the substrate,

by measuring electrical current that can be made to flow through existing pores in the coating material,

using the measuring probe of the test instrument.

Control unit with integrated storage case, without high voltage probe, but including :

- connecting cable probe/control unit

- metal sweeper electrode 200 mm

- earthing magnet

- earthing clamp

- equipotential cable

- power cable

- shoulder belt

- plastic carrying case

Suitable for factory & field spark testing the porosity of enameled (glass lined) surfaces at industrial applications, like agitators, chemical reactors, vessels, heat exchange panels, silo panels, water heaters, etc.

Data sheet

| Standards | DIN 55 670 |

| Properties | Testing voltage 0.5 – 35 kV |

| Electrical power | Power supply either by batteries or mains connection |