No products

Prices are tax excluded

Catalog

Various testing & inspection equipment typically used for process and/or quality control of porcelain (vitreous) enameled coatings.

Testing There are 68 products.

Subcategories

Finished goods

Various instruments for checking the quality / properties of a vitreous enamel coaitng

- adherence

- film thickness

- corrosion resistance

- mechanical impact

- porosity / holiday / spark tests.

Powder enamel

Various equipment for testing various powder enamel properties

Wet enamel

Various equipment for testing / quality control of wet enamel slip properties

Steel

Verification of steel properties pior to enameling

Furnaces

Classical "Banana" Gauge

Magnetic non-destructive coating thickness gauge for all non-magnetic coatings on steel and electro nickel on steel. No power supply No calibration Fully automatic

Ultrasonic coating thickness gauge

Ultrasonic Thickness gauge for measuring non-destructive of paint, varnish and all insulating coatings on plastic, wood, glass, ceramics, etc.Up to five layers in one measurement ! High accuracy and reproducibility through digital sensor technology SIDSP From 10μm up to 7mm film thickness

Spot Check Kit for shotblasting operations

Abrasive work-mixes play an important role in productivity and cleaning efficiency at shotblasting operations. This easy to use kit helps determine the “balance” of the abrasive work-mix as it wears smaller throughout its useful life. New abrasive additions are determined by the results of work-mix conditions and life cycles of abrasive. This kit will...

Rotational Viscometer

Rotational viscometers in several measuring ranges with optionally temperature measurement and PC interface.

Protective current meter

Protective current meter for verifying the enamel coating of water heaters according to DIN 4753-3

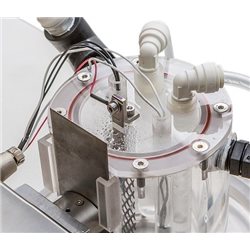

Fish scaling tester

Automated electrochemical permeation test equipment for enamels & steel, based on a solid-state-sensor for hydrogen measurements. Get reliable precise and continuous measurement of hydrogen flux without any time limit.

Powder Resistivity Meter

Powder resistivity is an important parameter at electrostatic powder coating operations. For this reason it is highly recommended to verify the resistivity of powder paint and/or powder enamels regularly. Features & benefits Accurate & repeatable resistivity measurements Easy to operate & clean Suitable for powder paint & powder enamel...

Furnace tracker with thermal barrier

Furnace tracker for determining the temperature profile of porcelain/vitreous enameling furnaces.